Have you ever questioned yourself how your car can easily switch gears without you taking any action as you press the accelerator? Out behind that polished experience is one of the most interesting engineering mechanisms in the automotive industry the automatic transmission.

Knowing how auto transmission works makes you admire the way modern cars give you easy acceleration, smooth rides and maximum fuel economy without you having to go through gears with your hand. Your car may have a conventional torque converter automatic gearbox, or it may have a Continuously Variable Transmission (CVT) or a Dual-Clutch Transmission (DCT), but the principle is the same. The transmission automatically controls the flow of power between the engine and the wheels.

We are going to dive deep into the working principle of automatic transmission, the primary types in the market today, and we will also define what is semi auto transmission, a common hybrid design that is known to fill the gap between a manual and an automatic transmission.

Table of Contents

Understanding the Purpose of a Transmission

It is important to know what a transmission does before we discuss the automatic system. A car engine generates a rotational power within a particular range of speed called revolutions per minute (RPM). But the driving conditions are never the same – you can run out of a stop, over hills, or thick traffic. The purpose of the transmission is to tune the engine power to the speed and torque demand of the vehicle.

In a manual car, you do this by adjusting the gear lever and the clutch by yourself. With an automatic car, however, all of this is done by machines and electronics, with no human input. In essence, the drive will be making sure that your vehicle accelerates smoothly, is powerful when required and consumes less fuel when cruising.

That is why your engine does not stall when you are waiting at a traffic light and does not strain itself in case you are on the highway.

Main Components of an Automatic Transmission

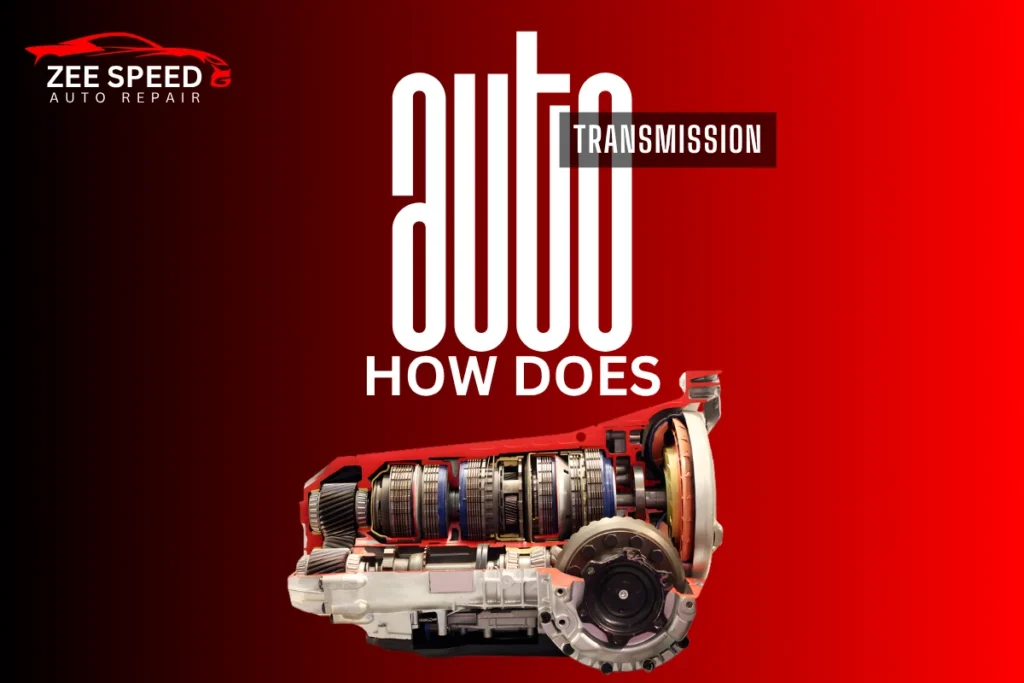

Automatics are works of art in their mechanical designs. They depend on a number of large pieces interacting together in harmony – the torque converter, planetary gear sets, and hydraulic or electronic control systems.

The Torque Converter

The torque converter lies at the centre of any automatic transmission. It takes the place of the traditional clutch in manual cars and attaches the engine to transmission. Rather than operating gears it utilizes transmission fluid to pass power. There are three main components of the torque converter: the pump, the turbine, and the stator.

The engine rotates the pump, forcing fluid to the turbine, which in turn rotates the input shaft of the transmission. They are separated by the stator, which diverts the flow of fluid and increases torque during acceleration.

This smart mechanism will enable your vehicle to idle in the gear, crawl past the traffic and provide you with smooth acceleration without failing to start the engine. Contemporary torque converters are also equipped with a so-called lock-up clutch, which is activated at higher speeds, leading to a better fuel economy and less slipping.

Planetary Gear Sets

Planetary gear sets give the actual gear ratios of an automatic transmission. The set is made up of one central sun gear and the rest are planet gears, an outer ring gear and a carrier that keeps the planet gears in place.

The transmission can produce various ratios through the locking and unlocking of these components in varying combinations, and thus, provide lower gears with greater torque and higher gears with more fuel efficiency. To give an example, when the sun gear remains stationary and the ring gear is rotated, you would have a lower gear ratio. In case of reversed roles, one gets overdrive.

A majority of contemporary transmissions employ multiple planetary gears sets that are stacked together. That is the reason you have six or eight or even ten forward gears in newer cars and it is all automatically controlled with no manual change in gears.

Hydraulic and Electronic Control Systems

The old automatics were only controlled by hydraulic pressure only to control the gear changes but the present systems are much more sophisticated. They operate a blend of hydraulics and computer controlled electronics.

Transmission Control Module (TCM) or Electronic Control Unit (ECU) constantly checks the values obtained by sensors that detect engine speed, throttle position and vehicle load. It uses this information to determine the time to change gears to achieve maximum efficiency and performance.

The flow of transmission fluid is then activated to open and close some clutches and bands that switch between gear ratios, using hydraulic solenoids. It is this smooth coordination between the mechanics and electronics that make the current automatics so responsive and smooth.

How Does Auto Transmission Work Step by Step

To get the concept of how auto transmission works, consider what happens when you pull up to a stoplight. As you turn on the engine, transmission fluid fills the torque converter, linking the engine to the gearbox. The more you press the accelerator, the faster the impeller (connected to the engine) rotates, forcing the fluid to flow into the turbine that converts the energy to the input shaft of the transmission.

The ECU monitors throttle position and speed. It sends signals to hydraulic-pressure adjusting solenoids when it detects that greater speed is needed. This makes certain clutches and bands connect and disconnect, holding different portions of planetary gear set together to establish new gear ratio.

All this takes a few fractions of a second before you sense the necessity of a gear change, and a moment later you have a consistent, smooth acceleration without any effort on the part of a manual gear change.

Types of Automatic Transmissions

Automatic transmissions do not operate in the same manner. With time, producers have produced different forms, each possessing distinctive features and advantages. Let’s explore the major ones.

Traditional Torque Converter Automatic

It is the most prevalent type in automobiles all over the world. It operates on a torque converter and planetary gears to handle shifts. Torque converter automatics are characterized by smooth, steady performance and durability. They fit well on normal vehicles and are a smooth ride to drive.

Although slightly less fuel-efficient than more modern designs, improvements such as lock-up clutches have made them much more efficient than the older models.

Continuously Variable Transmission (CVT)

The CVT is configured such that the gears are completely eliminated in favor of a belt-and-pulley system which offers an infinitely large number of ratios. A CVT varies the diameters of the pulleys to maintain the engines RPM at its most efficient speed, instead of changing between fixed gears.

This gives it good fuel economy and acceleration. The driving experience is however not as interesting to some drivers as no gear changes can be felt. CVTs are common in compact and hybrid vehicles that are used in urban environments.

Dual-Clutch Transmission (DCT)

A Dual-Clutch Transmission functions as two distinct gearboxes in one. It has two clutches (one to odd gears, the other to even gears) that enable it to pre-select the next gear when the current gear is still in gear.

The design produces high-speed gear changes and sportive ride. High-performance cars and luxury cars use DCTs, which are not only efficient but also thrilling. Nonetheless, they may be costlier to maintain because of their intricate installation.

Semi-Automatic Transmission (AMT)

Semi-automatic that is also called Automated Manual Transmission (AMT) is an automatic gearbox that integrates the ease of an automatic with the mechanical layout of a manual. No clutch pedal, sensors and actuators manage clutch engagement. The driver may opt to use paddle shifters to make manual shifts or allow the system to take care of the gear shifts. This is a much cheaper way of having the convenience of automatic driving.

Nonetheless, the transitions may be slower or slightly irregular in relation to full automatics. Semiautomatics are common in low-cost city automobiles and bikes. Similar technology is used in more complex paddle-shift systems in performance cars based on Formula One racing.

Common Problems and Maintenance for Automatic Transmissions

Even though the design of automatic transmissions is made to be durable, they still need attention. Delayed gears engagement, slipping, or jerky shifting may be some of the common problems. Such issues can be related to the low amount of transmission oil, damaged internal parts, or broken sensors.

Maintenance should be done regularly. The transmission fluid is to be inspected and replaced as per the manufacturer schedule- normally after every 40, 000 -60, 000 kilometers. The fluid is a lubricant and a coolant and ensures that the system runs smoothly.

You should also keep the cooling system of your car in good condition because overheating may ruin the transmission parts. The transmission control modules of modern vehicles occasionally require software upgrades, and therefore make sure that your car has an up-to-date ECU.

Choosing the Right Transmission for You

The different types of transmission are applicable to different driving preferences. A conventional automatic is the best choice in terms of comfort and reliability whereas CVT is best suited in terms of fuel efficiency in terms of commuting in the city. A DCT will give you the performance that you desire in a sporty performance and instant response.

Semi-automatic transmission is the best choice to drivers wishing to have the comfort of an automatic but with the affordability of a semi-automatic. The best option will be based on your lifestyle, driving patterns as well as budget.

The knowledge of how each type functions will enable you to make smarter choices when buying a car.

Understanding Semi-Automatic Transmissions in Depth

Speaking in more detail about semi-automatic transmissions, one can imagine that they are the transition between the manual and automatic ones. They keep the design of the manual gearbox intact and automate the functions of the clutch and the shifting triggers with the help of electronic actuators.

When you drive, there are sensors which check the speed of the engine, throttle input and the load of the vehicle. According to this data, the system determines when to leave the clutch, change gears and leave them, this is in milliseconds. What is achieved is an experience that is almost like a traditional manual but one does not have to press the clutch pedal to do so.

The semi-automatics have managed to gain significant popularity in such markets as India and Europe where people are most concerned about price and convenience.

Conclusion

And with the knowledge of how auto transmission works, you can really marvel at the technology that keeps your car in motion without much effort. Automatic transmissions combine the precision of mechanics with the intelligence of electronics to ensure that the gears of the vehicle shift smoothly and at an optimal performance and efficiency.

Whether you are driving a semi-automatic, CVT, DCT, or a classic torque-converter automatic, understanding how it works will ensure you can maintain it in better condition and make decisions when purchasing your next vehicle.

The next time you shift your car through the gears, keep in mind, under that smooth, quiet action, there is a multi-million-dollar orchestra of gears, hydraulics and control mechanisms all functioning together in harmony.

FAQs About How Does Auto Transmission Work?

How does auto transmission work in simple terms?

An automatic transmission has a torque converter and planetary gears which automatically adjust the gear ratios according to the speed and power requirement therefore the acceleration will be smooth with no manual shifts.

What is semi auto transmission?

A semi-automatic, or AMT, is an automation of the action of the clutch in a manual gearbox. It has automatic gear changes but still has a mechanical design, simple and convenient at the same time.

Why does my automatic transmission slip?

Transmission slip may be caused by a low level of fluid, old clutch packs, or defective solenoids. Getting your car serviced on time can save you a fortune.

How often should I change transmission fluid?

It is usually advisable to change it after every 40,000 to 60,000 kilometers, although it is always best to check the maintenance manual of your vehicle.

Is CVT better than a traditional automatic?

A CVT does provide a smoother acceleration and better fuel economy but some drivers might miss a traditional feel of shifting.

Can you tow with an automatic car?

Yes, be but careful what your manufacturer tells you. There are automatic systems, which need special modes or extra cooling to allow towing.